An industrial gas furnace is a thermal engineering device that uses gas as a heat source. It heats materials by burning gas and is used in metal processing, silicate industry and other fields to achieve physical or chemical changes. In metal processing, it is often referred to as a furnace, while in the silicate industry it is called a kiln. Its main structure includes a gas burner, furnace chamber, waste heat utilisation device and control system.

Nec piget dicere avide magis hanc insulam populum Romanum invasisse quam iuste. Ptolomaeo enim rege foederato nobis.

Nec piget dicere avide magis hanc insulam populum Romanum invasisse quam iuste. Ptolomaeo enim rege foederato nobis.

Nec piget dicere avide magis hanc insulam populum Romanum invasisse quam iuste. Ptolomaeo enim rege foederato nobis.

Nec piget dicere avide magis hanc insulam populum Romanum invasisse quam iuste. Ptolomaeo enim rege foederato nobis.

Nec piget dicere avide magis hanc insulam populum Romanum invasisse quam iuste. Ptolomaeo enim rege foederato nobis.

Designed by professional technical team, constructed by professional production team, efficient production speed, and more timely product delivery.

Strict quality inspection process ensures that every Yiran equipment leaving the factory is safe and of more reliable quality.

Integrating R&D, design, production, installation and commissioning, we customize each heating equipment for customers

Strategic cooperation with high-quality raw material suppliers ensures product quality.

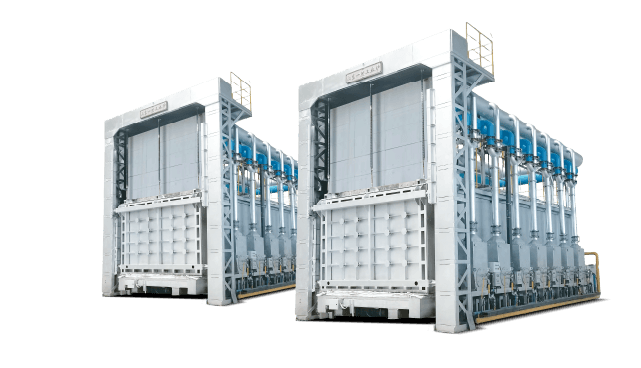

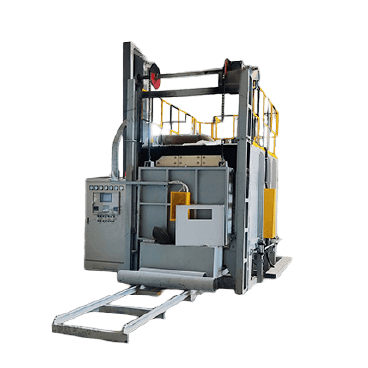

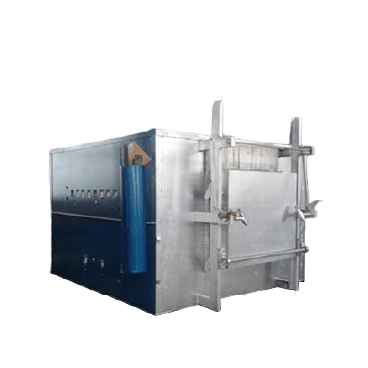

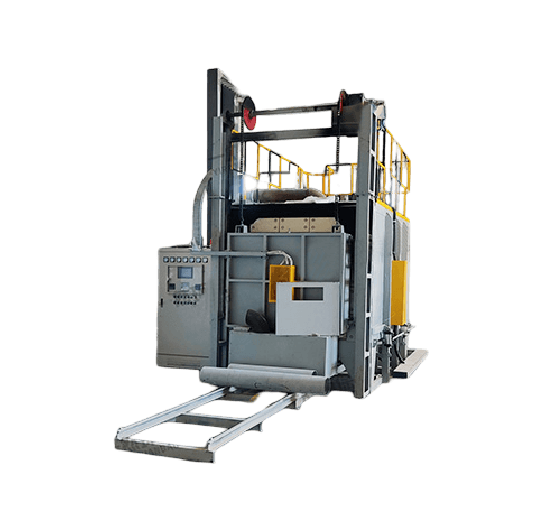

Founded in 2013, Shandong Yiran Environmental Protection Technology Co., Ltd. is a large-scale manufacturing enterprise integrating industrial furnace technology research and development, production and manufacturing, guidance services and commodity trade. The main products are natural gas forging heating furnace, regenerative trolley furnace, heat treatment furnace and other energy-saving industrial furnaces.

We have more than 30 patents, including 5 invention patents, and have passed ISO9001-2008 certification.

Two production bases, spanning over 30,000㎡, with 200+ skilled workers and an annual output of 500+ heating furnaces.

Full installation, training, 24/7 support — we keep your business running at its best.

Using natural gas and air reversing self-regenerative high-speed burner to achieve full temperature section heat recovery.

Using natural gas and air reversing self-regenerative high-speed burner to achieve full temperature section heat recovery.

Using natural gas and air reversing self-regenerative high-speed burner to achieve full temperature section heat recovery.

Using natural gas and air reversing self-regenerative high-speed burner to achieve full temperature section heat recovery.

Using natural gas and air reversing self-regenerative high-speed burner to achieve full temperature section heat recovery.

Using natural gas and air reversing self-regenerative high-speed burner to achieve full temperature section heat recovery.

Using natural gas and air reversing self-regenerative high-speed burner to achieve full temperature section heat recovery.

Post emensos insuperabilis expeditionis eventus languentibus partium animis, quas periculorum varietas fregerat et laborum, nondum tubarum cessante clangore vel milite locato per stationes hibernas, fortunae saevientis procellae tempestates alias rebus infudere communibus per multa illa et dira facinora Caesaris Galli, qui ex squalore imo miseriarum in aetatis adultae primitiis ad principale culmen insperato saltu provectus ultra terminos potestatis delatae procurrens asperitate nimia cuncta foedabat. propinquitate enim regiae stirpis gentilitateque etiam tum Constantini nominis efferebatur in fastus, si plus valuisset, ausurus hostilia in auctorem suae felicitatis, ut videbatur.

Employs cutting-edge eco-friendly technologies to craft green industrial furnaces, contributing to global carbon reduction efforts and a shared dream of a clearer sky.